In various applications such as materials processing, laser surgery, and remote sensing, there are widely used general-purpose laser systems, many of which share common key parameters. Establishing generic terms for these parameters can prevent communication errors, and understanding them correctly can specify laser systems and components to meet application requirements.

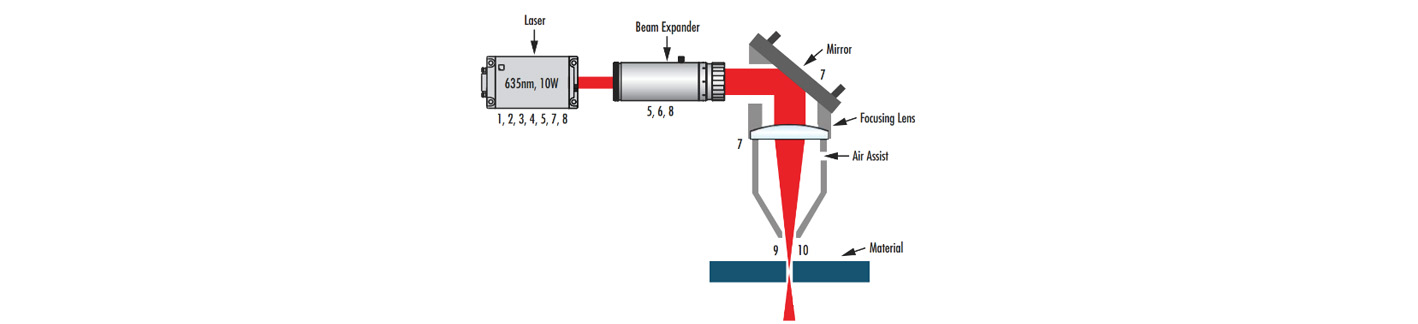

Figure 1: Schematic diagram of a common laser material processing system, with each of the 10 key parameters of the laser system represented by corresponding numbers.

Basic Parameters

The following basic parameters are fundamental concepts of laser systems and are crucial for understanding more advanced points.

1: Wavelength (typical units: nm to μm)

The wavelength of a laser describes the spatial frequency of the emitted light wave. The optimal wavelength for a given use case highly depends on the application. Different materials exhibit unique wavelength-dependent absorption characteristics in materials processing, leading to different interactions with the material. Similarly, atmospheric absorption and interference affect different wavelengths differently in remote sensing, while various complexes in medical laser applications absorb different wavelengths differently. Shorter wavelength lasers and laser optical devices are advantageous for creating small and precise features with minimal peripheral heating since the spot size is smaller. However, they are typically more expensive and more prone to damage than longer wavelength lasers.

2: Power and Energy (typical units: W or J)

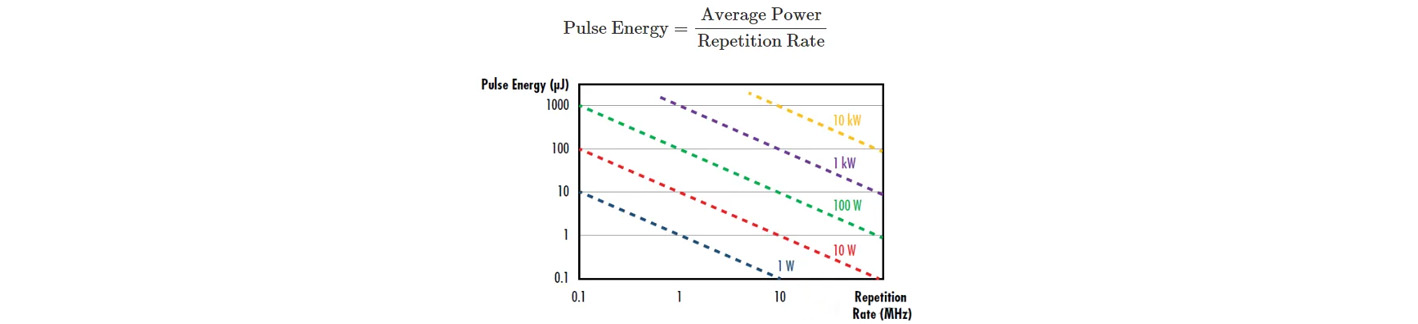

The power of a laser is measured in watts (W) and is used to describe the optical power output of continuous-wave (CW) lasers or the average power of pulsed lasers. Pulsed lasers are also characterized by their pulse energy, which is proportional to the average power and inversely proportional to the laser’s repetition rate (Figure 2). Lasers with higher power and energy are usually more expensive and generate more waste heat. As power and energy increase, maintaining high beam quality also becomes increasingly challenging.

3: Pulse Duration (typical units: fs to ms)

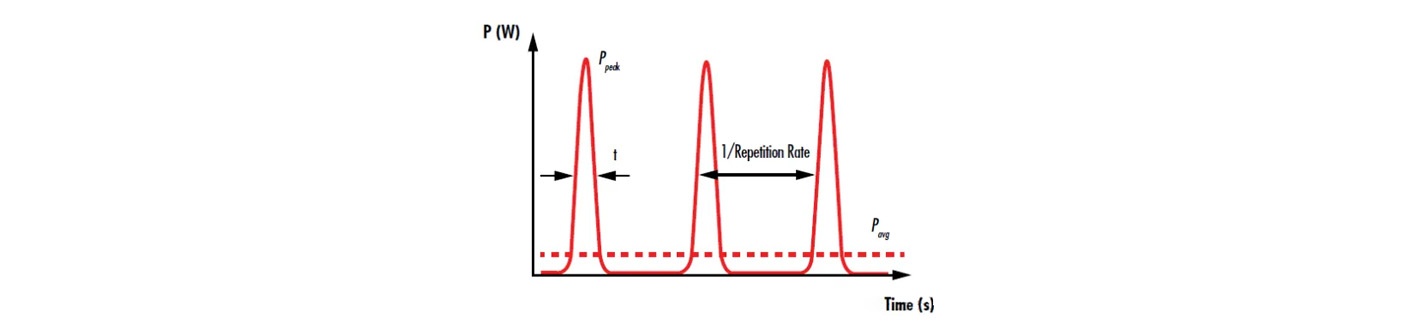

The laser pulse duration or pulse width is typically defined as the full width at half maximum (FWHM) of the laser optical power versus time (Figure 3). Ultrafast lasers offer many advantages in a range of applications, including precise materials processing and medical lasers, characterized by short pulse durations, typically ranging from picoseconds (10-12 seconds) to attoseconds (10-18 seconds).

4: Repetition Rate (typical units: Hz to MHz)

The repetition rate or pulse repetition frequency of a pulsed laser describes the number of pulses emitted per second or the inverse of the time between pulses (Figure 3). As mentioned earlier, the repetition rate is inversely proportional to the pulse energy and directly proportional to the average power. While the repetition rate typically depends on the laser gain medium, it can vary in many cases. A higher repetition rate leads to shorter thermal relaxation times on the surfaces of laser optical devices and the final focal point, resulting in faster material heating.

5: Coherence Length (typical units: mm to m)

Lasers are coherent, meaning there is a fixed relationship between the phase values of the electric field at different times or positions. This is because, unlike most other types of light sources, lasers are generated by stimulated emission. Coherence degrades throughout the propagation process, and the coherence length of a laser defines a distance over which the laser’s temporal coherence remains at a certain quality.

6: Polarization

Polarization defines the direction of the electric field of the light wave, which is always perpendicular to the direction of propagation. In most cases, the laser will be linearly polarized, meaning the emitted electric field always points in the same direction. Unpolarized light will have electric fields pointing in many different directions. Polarization is typically expressed as the ratio of intensities between two orthogonal polarization states, such as 100:1 or 500:1.

Beam Parameters

The following parameters characterize the shape and quality of the laser beam.

7: Beam Diameter (typical units: mm to cm)

The beam diameter of a laser describes the lateral extent of the beam or its physical size perpendicular to the direction of propagation. It is typically defined as the 1/e2 width, where the intensity of the beam reaches 1/e2 (≈ 13.5%). At the 1/e2 point, the electric field strength decreases to 1/e (≈ 37%). A larger beam diameter requires larger optical devices and the entire system to avoid beam truncation, thus increasing costs. However, reducing the beam diameter increases the power/energy density, which can also be detrimental.

8: Power or Energy Density (typical units: W/cm2 to MW/cm2 or µJ/cm2 to J/cm2)

The beam diameter is related to the power/energy density of the laser beam or the optical power/energy per unit area. The larger the beam diameter, the lower the power/energy density of a beam with constant power or energy. High power/energy density is typically desirable at the final output of a system, such as in laser cutting or welding, but low power/energy density inside the system is often beneficial to prevent laser-induced damage. This also prevents ionization of air in regions of high power/energy density of the beam. For these reasons, beam expanders are often used to increase the diameter, thus reducing the power/energy density inside the laser system. However, care must be taken not to expand the beam too much to avoid blocking the beam from apertures in the system, resulting in energy waste and potential damage.

9: Beam Profile

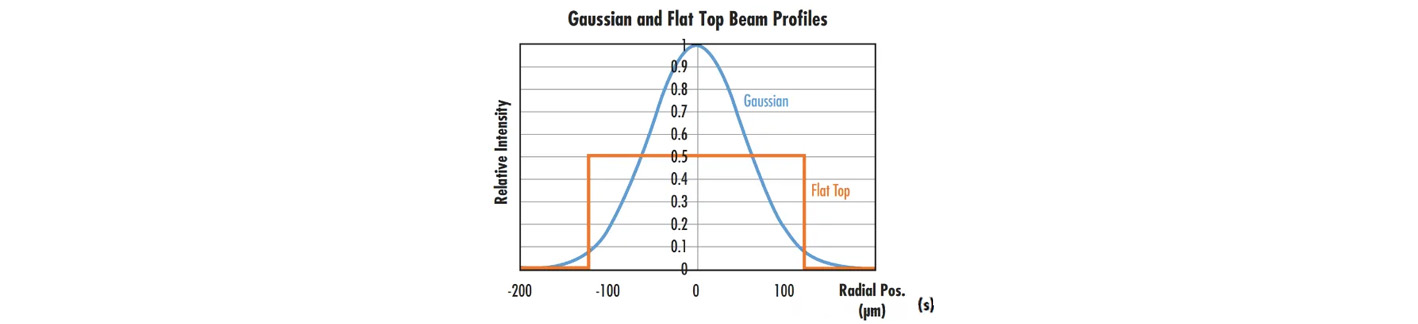

The beam profile of a laser describes the intensity distribution on the beam’s cross-section. Common beam profiles include Gaussian beams and flat-top beams, whose beam profiles follow Gaussian and flat-top functions, respectively (Figure 4). However, no laser can produce a beam profile that exactly matches its characteristic function of a fully Gaussian or fully flat-top beam because there are always some amount of hotspots or fluctuations inside the laser. The difference between the actual beam profile of the laser and the ideal beam profile is often described by metrics including the laser’s M2 factor.

10: Divergence (typical units: mrad)

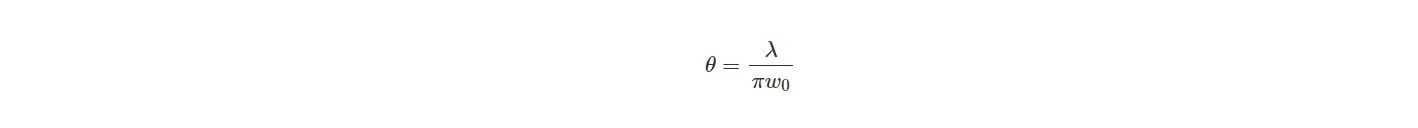

While laser beams are typically considered collimated, they always contain some amount of divergence, which describes the extent to which the beam diverges as it travels farther from the laser’s waist due to diffraction. In applications with long working distances, such as laser radar systems, where objects may be hundreds of meters away from the laser system, divergence becomes a particularly important consideration. Beam divergence is typically defined by the half-angle of the laser, with the divergence of a Gaussian beam (θ) defined as:

λ is the wavelength of the laser, w0 is the waist of the laser.

Final System Parameters

These final parameters describe the performance of the laser system at its output.

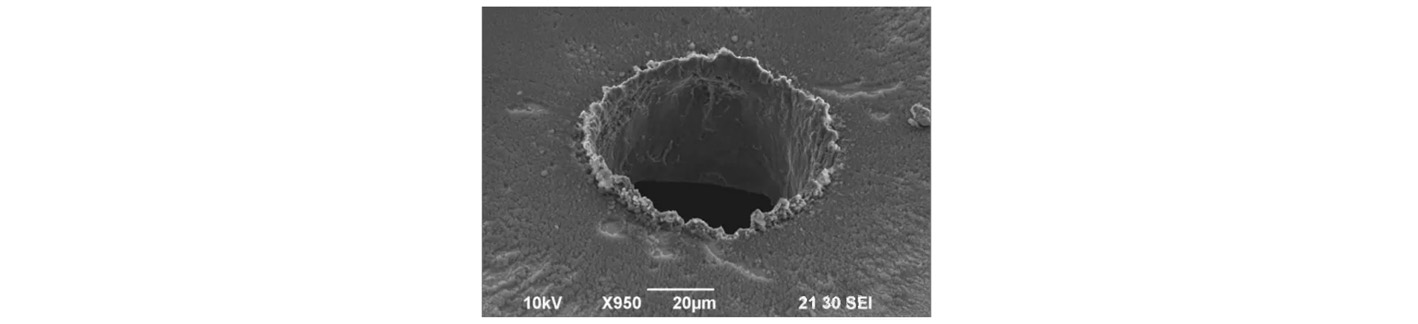

11: Spot Size (typical units: µm)

The spot size of a focused laser beam describes the diameter of the beam at the focus of the focusing lens system. In many applications, such as materials processing and medical surgery, the goal is to minimize the spot size. This maximizes the power density and allows for the creation of extremely fine features (Figure 5). Non-spherical lenses are often used instead of traditional spherical lenses to reduce spherical aberration and produce smaller spot sizes. Certain types of laser systems may not ultimately focus the laser to a spot, in which case this parameter is not applicable.

12: Working Distance (typical units: µm to m)

The working distance of a laser system is typically defined as the physical distance from the final optical element (usually the

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。

![[galvo laser scanner]Exploring the Advancements and Applications of Galvo Laser Scanners in Precision Manufacturing and Industrial Automation](https://www.ezcadchina.com/wp-content/uploads/2024/07/Is-Mopa-laser-better-than-fiber-laser-500x383.jpg)

![[optical fiber laser marking machine]Understanding the Versatility and Benefits of Optical Fiber Laser Marking Machines in Modern Manufacturing and Industrial Applications](https://www.ezcadchina.com/wp-content/uploads/2024/05/Application-of-large-size-intelligent-continuous-laser-processing-system-500x383.jpg)