[laser cutter co2]The CO2 Laser Cutter: A Guide to Its Uses and Benefits

News 2025-7-28

The CO2 laser cutter is an indispensable tool for a wide range of manufacturing and production industries, revolutionizing the way materials are processed and cutting down production times significantly. With its precision and versatility, the CO2 laser cutter stands out as a reliable tool for various cutting applications. Here's a guide to the uses and benefits of the CO2 laser cutter.

The CO2 Laser Cutter: A Guide to Its Uses and Benefits

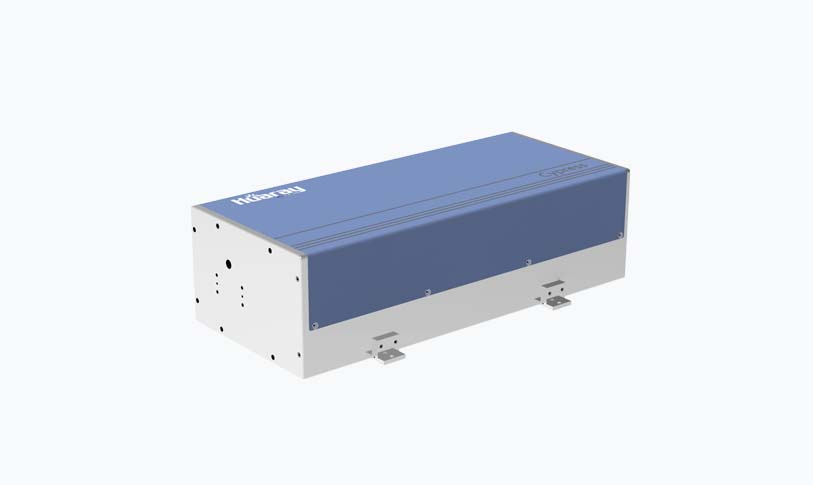

CO2 laser cutters are machines that use a beam of focused laser light to cut through different materials. They emit an infrared beam that is absorbed by the material being cut, converting it into thermal energy, which then vaporizes the material, resulting in a clean cut. CO2 laser cutters are particularly suitable for cutting non-metallic materials like wood, paper, cardboard, plastic, and rubber.

The CO2 Laser Cutter: A Guide to Its Uses and Benefits

CO2 laser cutters are widely used in various industries due to their versatility and precision. Some of the common applications of CO2 laser cutters include:

The CO2 Laser Cutter: A Guide to Its Uses and Benefits

Benefits of CO2 Laser Cutters

1. Precision Cutting: CO2 laser cutters offer high-precision cutting with minimal error margins, ensuring accurate cuts even in intricate designs. 2. Versatility: These cutters can handle different materials, ranging from thin paper to thick wood, with ease. 3. Speed and Efficiency: CO2 laser cutters offer fast cutting speeds, reducing production time and increasing efficiency. 4. Clean Cuts: The heat generated by the laser beam ensures clean and smooth cuts without any burrs or rough edges. 5. Non-Contact Cutting: CO2 laser cutters offer non-contact cutting, which means there's no physical contact between the cutting tool and the material, reducing the chances of material damage or operator injury. 6. Easy to Use and Maintain: Modern CO2 laser cutters come with user-friendly interfaces and are easy to operate and maintain, reducing downtime and increasing productivity.

CO2 laser cutters are a great investment for businesses that require precise and efficient cutting of different materials. With their versatility and range of applications, these cutters can handle various tasks, making them an indispensable tool in various industries. If you're looking for a reliable and efficient cutting solution, consider investing in a CO2 laser cutter.