[fiber laser software]The Evolution of Fiber Laser Software: Advancements and Applications

News 2025-7-13

The Evolution of Fiber Laser Software: Advancements and Applications

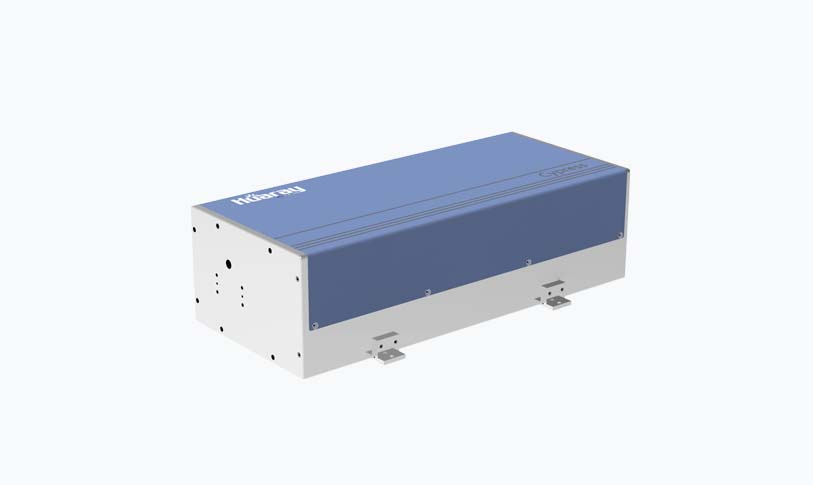

The fiber laser software is designed to control the laser's parameters such as power, frequency, and pulse duration, enabling precise material processing. The software's interface is user-friendly and can be easily operated by non-experts as well as professionals. It offers a range of features that enable users to customize their laser operations according to their specific needs.

The Evolution of Fiber Laser Software: Advancements and Applications

Another notable advancement is the integration of fiber laser software with other manufacturing technologies. For instance, it can be integrated with CNC machines, 3D printers, and other industrial robots to form a fully automated manufacturing system. This integration significantly improves productivity and reduces the need for human intervention.

The fiber laser software is also being used in various applications. In the manufacturing industry, it is used for cutting, welding, and engraving different materials such as metal, wood, and glass. In the medical field, fiber lasers are used for surgical procedures such as skin rejuvenation and eye surgery, with the software enabling precise control over the laser's parameters.

Moreover, the fiber laser software has also found its applications in other fields such as aerospace, automotive, and electronics. In aerospace, it is used for precision cutting and welding of aircraft components. In automotive, it is used for manufacturing car parts such as interior trims and exterior bodies. In electronics, it is used for cutting and engraving electronic components with high precision.

The Evolution of Fiber Laser Software: Advancements and Applications

In conclusion, fiber laser software has played a crucial role in the success of fiber laser technology. With ongoing advancements and applications in various industries, it is expected to continue evolving in the future, enabling more efficient and precise manufacturing processes.