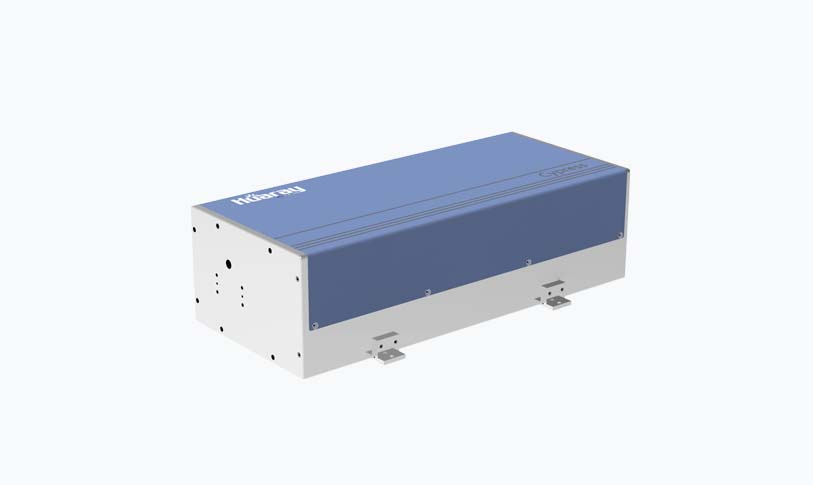

[360 nm laser]The Application of 360 nm Laser Technology in Modern Industries and its Advantages

News 2025-7-10

In recent years, the utilization of cutting-edge technologies has profoundly revolutionized numerous sectors. Among them, the advent of 360 nm laser technology has revolutionized several fields such as manufacturing, medicine, and materials processing. This article delves into the application of 360 nm laser in modern industries and its advantages.

What is a 360 nm Laser?

Before discussing its applications and advantages, it is essential to understand what a 360 nm laser is. A 360 nm laser produces a beam of light with a wavelength of 360 nanometers, which falls in the UV-C range of the electromagnetic spectrum. This type of laser is known for its high energy and precision, making it suitable for various applications.

Applications of 360 nm Laser in Modern Industries

1. Manufacturing: In the manufacturing sector, 360 nm laser technology is used for precision cutting, drilling, and welding. Its high-energy beam allows for precise cuts with minimal material deformation, enhancing product quality and production efficiency.

The Application of 360 nm Laser Technology in Modern Industries and its Advantages

The Application of 360 nm Laser Technology in Modern Industries and its Advantages

Advantages of 360 nm Laser Technology

1. Precision: The precision offered by 360 nm lasers is unparalleled. The high-energy beam allows for precise cutting, drilling, welding, and treatment with minimal errors.

2. Non-Contact Operation: 360 nm lasers operate without physical contact with the material being processed, reducing the risk of damage and contamination.

3. High Speed: The speed of 360 nm lasers is impressive, enabling faster production and processing times.

4. Cost-Efficiency: Although the initial investment for 360 nm laser technology might be high, its long-term operational costs are low, leading to cost savings in terms of maintenance and labor costs.

5. Versatility: 360 nm lasers can be used in various applications across different industries, making them highly versatile tools.

The Application of 360 nm Laser Technology in Modern Industries and its Advantages

The application of 360 nm laser technology in modern industries has revolutionized various sectors such as manufacturing, medicine, and materials processing. Its precision, non-contact operation, high speed, cost-efficiency, and versatility make it a valuable tool for various applications. As technology continues to evolve, the potential uses and advantages of 360 nm lasers will further expand in the coming years.