[laser cutting machine software]Exploring the Impact of Laser Cutting Machine Software on Efficiency and Precision in Manufacturing and Crafting Industries

News 2025-2-5

In recent years, laser cutting has revolutionized various industries, from manufacturing to arts and crafts. The core of this transformation lies in advanced laser cutting machine software. This software not only enhances the operational efficiency of laser cutting machines but also significantly improves the precision of cuts, leading to higher quality products. In this article, we will delve into the importance of laser cutting machine software, its functionalities, and how it is shaping the future of both industrial manufacturing and personalized crafting.

Understanding Laser Cutting Technology

Laser cutting utilizes focused laser beams to cut through materials with high precision. This technology is widely employed in various materials, including metals, plastics, wood, and even textiles. The laser cutting process involves directing a high-powered laser, which melts, burns, or vaporizes the material, allowing for intricate designs and clean edges.

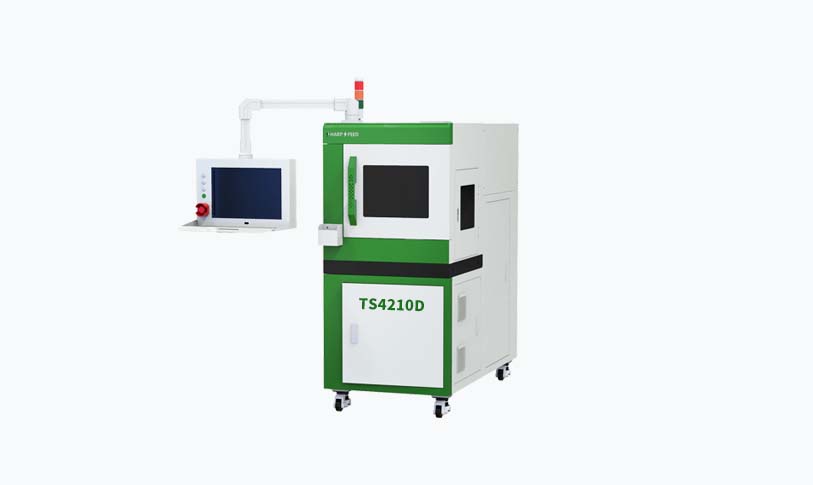

While the hardware (the laser cutting machine) is essential, it is the software that drives the machine's capabilities. The right laser cutting machine software can optimize the entire cutting process, improving efficiency, reducing waste, and ensuring precision.

The Role of Software in Laser Cutting

Laser cutting machine software is a crucial component that translates design files into instructions that the laser cutter can execute. The most common software functionalities include:

1. **Design Importing**: The software allows users to import designs from various graphic design programs, such as AutoCAD, Adobe Illustrator, or CorelDRAW. This versatility ensures that users can work with the design tools they are most comfortable with.

2. **Path Optimization**: Laser cutting machine software analyzes the cutting path to minimize material wastage and reduce cutting time. By optimizing the sequence in which cuts are executed, the software ensures efficiency and lowers operational costs.

3. **Settings Control**: The software controls various settings, such as laser power, speed, and frequency, which can be adjusted based on the type of material being cut. Fine-tuning these parameters is vital for achieving desired outcomes, especially when dealing with different thicknesses and densities of materials.

4. **Simulation and Preview**: Many software packages offer simulation features that allow users to preview the cutting process before actual execution. This ensures that any potential issues can be addressed beforehand, saving time and resources and minimizing errors.

5. **User-Friendly Interface**: Modern laser cutting machine software prioritizes user experience. With intuitive interfaces, even those with minimal technical knowledge can operate complex machines effectively. Features like drag-and-drop design placement, easy adjustment of cutting parameters, and real-time monitoring make the process much more manageable.

Benefits of Using Advanced Laser Cutting Machine Software

1. **Increased Precision**: With sophisticated algorithms, the software enhances the precision of cuts, reducing the tolerance levels and ensuring intricate designs can be executed flawlessly. This is particularly valuable in industries such as aerospace and automotive, where every millimeter counts.

2. **Enhanced Workflow**: Streamlined processes reduce the time between design and production. Businesses can meet tight deadlines and fulfill orders more effectively, an essential factor in today’s fast-paced market.

Exploring the Impact of Laser Cutting Machine Software on Efficiency and Precision in Manufacturing and Crafting Industries

4. **Customization**: For craftspeople and small businesses, laser cutting machine software allows for easy customization of designs. Whether creating personalized gifts, custom signage, or prototype models, the software facilitates bespoke production efficiently.

5. **Integration with Other Technologies**: Many laser cutting software solutions can integrate with other manufacturing technologies, like CNC (Computer Numerical Control) machining and 3D printing. This integration enhances the overall production workflow, enabling businesses to offer comprehensive solutions.

Exploring the Impact of Laser Cutting Machine Software on Efficiency and Precision in Manufacturing and Crafting Industries

As technology continues to evolve, so too will laser cutting machine software. The future may bring about greater automation, artificial intelligence capabilities, and enhanced compatibility with various materials and processes. Such advancements could lead to even higher efficiency levels and broaden the applications of laser cutting across different industries.